+86-0731-88911542

sales@bhomeglobal.com

+86-0731-88911542

sales@bhomeglobal.com

CurrentLocation:Home > Technology > Technology System

What is PC?

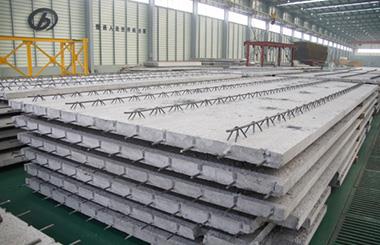

PC (Precast concrete) is a construction product produced by casting concrete in the factory, transported to the jobsite and then erected.

Composite slab

Sandwich wall panel

Exterior wall

Composite floor slab

Composite beam

Stair

Technology System

Technology System

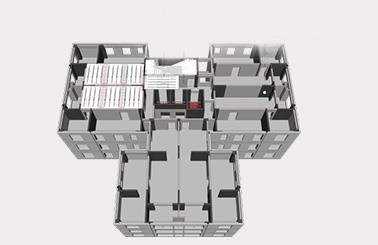

Broad technology and manufacturing

Broad Homes’ 5th generation of industrialized integrated building system adopts the world’s most advanced precast concrete technology and BIM platform. By optimizing the R&D system, design system, manufacturing system, construction system, material system and product system quality is improved and time, energy and cost can be saved.

Through standardization and industrialization, we adopted a flexible production line to produce PC, which can greatly reduce the labor and shorten production period while ensuring product quality and efficiency.

Seismic resistance

With higher seismic resistance performance the structure system of industrialized building is equal to the structure system of cast-in-situ.

Structure system of high-rise building

Structure system of multi-story building

Water-proofing

The housing facades are decorated by graphic precast veneer and the decoration process is finished in the factory. The gaps of exterior wall are filled with polyurethane sealant, which is flexible, durable, easy to form, maintainable and paintable. It is efficient under the effects of structure creep, solarization, melt-freeze cycle, and acid rain. The doors & windows can be installed in factory or on-site. Connectors are embedded during precast.

Thermal-insulation and sound-proofing

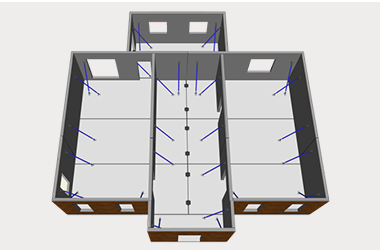

Precast sandwich wall panel has excellent thermal-insulation and sound-proofing performance as the insulation layer can insulate heat and absorb sound.

Fire-proofing

Fire barrier is set on each floor as to prevent fire from spreading.

Graphic veneer

Graphic veneer can be prefabricated in the PC factory with the wall.

Higher speed and controllable construction period

All the PC components are prefabricated in the PC factory and cured in the curing chamber with higher precision. Productivity is dramatically enhanced by automated streamline, mechanized installation and synchronized decoration to guarantee product quality. The precast construction process not only ensures construction safety by eliminating scaffolds, but also improves efficiency. It only takes 9 months to construct a 30-storey building with refined decoration from production to delivery. Efficiency is enhanced by 35 times compared to traditional construction methods.

Controllable cost

The cost of industrialized building more controllable compared to conventional building due to fast capital turnover, low financing costs and reduced engineering management costs.

Energy-saving and environmental-friendly

Compared to traditional buildings, industrialized buildings substantially reduce impact on the environment.

Clean and tidy construction site leads to less accident

Clean and tidy construction site leads to less accident

No sewage pollution in PC factory and construction site

No sewage pollution in PC factory and construction site

Noise is greatly reduced in the course of construction.

Noise is greatly reduced in the course of construction.

Dust free

Dust free

Decreased building waste

Decreased building waste

Broad site

Conventional site

Add(Changsha):5F/Bldg.9, Changsha CEC Software Park, 39 Jianshan Rd, Yuelu District, Changsha, Hunan Province, China Tel:+86-0731-88600277 E-mail:info@bhomeglobal.com

Add(Hongkong):Suite 1104-05, 11/F, Great Eagle Center 23 Harbour Road, Wanchai, Hongkong. Tel:(852)25730001

Add(Suriname): Copernicusstraat 69, Paramaribo

Copyright@All Rights Reserved By Broad Homes Industrial International Co., Ltd.